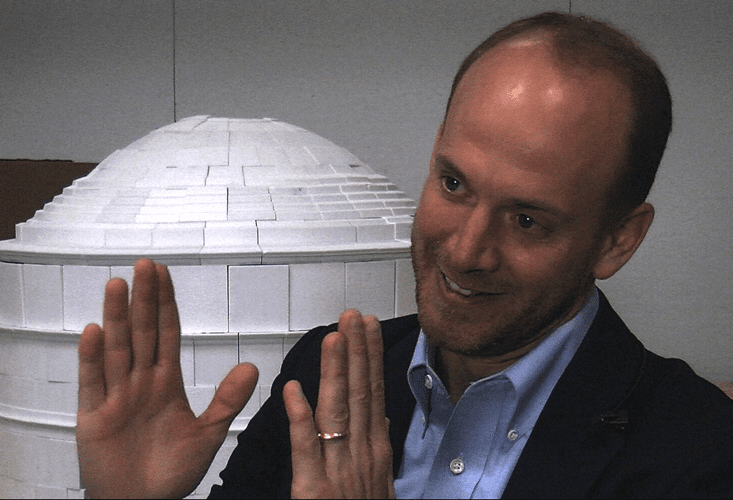

John Ochsendorf wants to tear down Rome’s iconic Pantheon. He wants to pull apart its 2,000-year-old walls until its gorgeous dome collapses. Destroying it, he believes, is the best way to preserve it.

But the Pantheon that Ochsendorf, a professor of engineering and architecture at the Massachusetts Institute of Technology, has in mind to destroy is less than 20 inches high, and it’s made of 492 3-D-printed blocks. It’s designed from laser scans of the real building. A gaggle of MIT engineering students will place it on a table with a sliding base and pull the walls apart, then put it back together and tilt it until it crumbles.

It’s hard to see how razing a doll-sized Roman monument will help protect the real thing. But Ochsendorf, whose easy smile and self-effacing humor belie confidence and determination, has a serious goal: to prove that historical structures like the Pantheon are more stable than we give them credit for. “By every measure of success of a building—from an architectural, from an artistic, and from an engineering standpoint—I would argue that the Pantheon is the greatest that was ever built,” Ochsendorf says. “There’s no greater definition of success for a building than it’s been standing for 20 centuries.”

It also represents a masterwork of engineering and a repository of ancient technical knowledge—the structural equivalent of the Mona Lisa. Ochsendorf is working to halt what he sees as unnecessary interventions in historical buildings, in which engineers try to fix cracked or slumping walls with steel bars and supports. “We see a crack in a structure and we do a major intervention, but that’s akin to dipping the Mona Lisa in epoxy because one section of the painting has faded a bit,” he says.

His work indicts the short-sightedness of today’s engineers as it underscores the wisdom of the past.

Some interventions, designed to keep today’s tourists safe, might deteriorate in a few decades and damage long-lived monuments for future generations. But they may also be unnecessary. Many interventions arise, Ochsendorf believes, from a fundamental misunderstanding of how buildings like these behave.

“Too often, we’re trying to make old structures conform to theories we learned for steel and concrete,” he says. Those materials remain strong under immense stresses in modern buildings. But buildings like the Pantheon “stand because of their geometry,” he says, “and the way builders conceived them was really through their geometry.” Cracks and deformations, he argues, are not necessarily flaws; they’re often a sign that a building adapted to a sinking foundation centuries ago and found a new conformation. “We should conserve the great works of construction for future generations, and that means understanding what the original builders intended, and trying to be faithful to their intent.”

Ochsendorf, though, is more than a preservationist. His work, influenced by leading thinkers in structural theory before him, indicts the short-sightedness of today’s engineers as it underscores the engineering wisdom of the past. “We have this notion that we’re at the pinnacle of all time,” Ochsendorf says. It’s not that he thinks engineers should create new Pantheons, any more than contemporary poets should write Shakespearean sonnets. But he does say that studying masterworks makes better writers, artists, architects, and musicians. “I personally believe that by studying the greatest works of engineering of the past, we can produce better engineers in the future.”

Before iron, steel, and steel-reinforced concrete changed architecture forever, most civilizations made large buildings out of masonry: stones, bricks, mortar, and unreinforced concrete like the kind that ancient Romans used to construct the Pantheon’s dome. Builders relied on rules based on accumulated experience. The foundations of their designs were arches and vaults, which allowed heavy and brittle materials to reach long spans and soaring heights.

“A fundamental design goal was to build for generations, and to build for posterity,” Ochsendorf says. Builders chose granite, marble, and other durable materials. “They were working at a very high level and with high stakes,” he says. “If you invest the equivalent of millions of dollars into a structure, you don’t want to invest it in some amateur who doesn’t know if it’s going to stand up or not,” he says.

The Pantheon, which was completed in 125, is one example of such a high-stakes building. Its Greek-style, columned portico opens up into a massive rotunda, topped by a concrete dome that extends 142 feet in height, the largest unreinforced concrete dome in the world, with an open oculus that lets light, rain, and the occasional snowflake onto the floor below. It has withstood centuries of storms, earthquakes, abandonment, and reuse, in spite of wide fissures snaking up its dome.

With the Industrial Revolution, new materials changed buildings forever. They made it possible to create higher and broader structures with fewer resources. Building codes—uniform standards for building materials and design—which proliferated after the great urban fires of the 19th century, helped to phase old ways of building out of existence. They made buildings far safer, but paradoxically shut the door on ways of building that had been used for millennia.

Because engineers were no longer building with unreinforced masonry, they developed new mathematical techniques and software for analyzing concrete and steel. “We basically threw out 3,000 years of knowledge of vaulting and about arches,” Ochsendorf says. “And so ironically, that means that despite all our sophisticated technology today, we’re not in a great position to say how safe the Pantheon is.”

Ochsendorf, who has won plenty of accolades, including a MacArthur “genius” Fellowship in 2008, has the prickly tenacity of someone who’s chosen to work against the mainstream of his field. His appreciation for tradition can be traced back to his upbringing in a small town in West Virginia, where he was raised in a household with no TV, surrounded by artisans who made their own fiddles and banjos. He studied a blend of engineering and archaeology at Cornell University, and in graduate school at Cambridge University in England, he came under the wing of Jacques Heyman, the head of the department of engineering. He spent a year on a Fulbright fellowship with Santiago Huerta, a historic masonry specialist at the Technical University of Madrid, Spain, one of Heyman’s disciples.

Heyman is known for an approach to analyzing structures called plasticity theory, which was originally applied to steel structures but that he adapted for unreinforced masonry buildings. After he published a seminal paper in 1966, “The Stone Skeleton,” he became a leading figure in church and cathedral architecture and restoration in England.

The gist of the theory, Heyman explains to me, is that if a structure has any way of standing up, it will. Engineers don’t need to make elaborate calculations of the internal stresses acting in every part of a building to determine its safety. “It is impossible to calculate the way a structure actually stands up,” he says. “All the engineer has to do is find one way that the structure could stand up.”

The way that unreinforced masonry buildings stand is by finding equilibrium. Masonry is tremendously strong under forces of compression, which squeeze the material, but it has almost no strength under forces of tension, which pull the material apart. In 1675, English scientist Robert Hooke noted that a hanging chain makes the same curve, but inverted, as a standing arch. The reason is that both are in equilibrium, the chain in tension and the arch in compression. Even before Hooke, ancient builders managed to create large masonry buildings by finding geometries—arches, domes, and vaults—in which the materials are subject only to compression, rather than tension. A flat ceiling or bridge made of stones would easily collapse because of tension; shape the stones into an arch, however, and you can span a wide distance.

The downward thrust from the top of an arch creates outward pressure on the walls, which must be resisted by buttresses. Builders used proportional design rules to produce stable structures. Divide the span of a vault in a Gothic cathedral by 10 to get the thickness of walls, for instance, and multiply that number by three for the thickness of the buttresses.

“It’s like you have a scar on your arm from an accident that happened 30 years ago—to come along and say, ‘We have to operate.’ ”

Huerta says science has often denigrated this type of design strategy, dating back to the 17th century and Galileo, who studied the strength and stiffness of materials. Galileo realized that a bigger beam is proportionately weaker than a smaller one, so a bigger structure would require proportionally thicker supports. He used this idea, now called the square-cube law, to explain why building height has a limit and why a giant animal could not exist without massively distorted bones (an idea famously described in J.B.S. Haldane’s essay “On Being the Right Size”).

Gallileo’s law applies beautifully to modern structures, which push materials close to their limits of strength. But it was a deliberate break from the rules about proportion that builders followed in his own time. Huerta says that Galileo was wrong in thinking his law applied to the cathedrals of his day. “He was creating a new science, and studying the problem of strength, but in masonry structures, the problem is not strength, it’s stability,” he says.

The compressive forces of a well-designed arch don’t come close to the limits of masonry’s strength in compression. That’s why a 50-foot vault can have the same proportions as a 100-foot vault without collapsing. Questions of strength are moot; what matters is that the structure is stable. “A historical structure is safe because it has a correct geometry,” says Huerta. He adds that engineers today often think like Galileo when they evaluate historical buildings; they see cracks and worry about strength. “The problem is in their heads, not in the real building that has stood for centuries,” Huerta says.

Ochsendorf agrees. “The cracked state is the natural state of the masonry building,” he says. In many cases, cracks form when foundations settle unevenly, often within a couple of decades of a building’s life. “The original builders would not have been happy with the cracks,” Ochsendorf admits, but they likely knew the difference between a crack that was part of a natural settling process and one that heralded collapse. Today, engineers have lost that perspective. “It’s like you have a scar on your arm from an accident that happened 30 years ago—to come along and say, ‘We have to operate, have you seen this scar?’ ”

Assessing and repairing historical structures is a fraught process: In earthquake-prone areas like Italy, the collapse of older churches and monuments can be devastating, yet there are plenty of examples of misguided interventions to strengthen buildings. Iron and steel beams installed in masonry walls in the early 20th century have corroded and swollen over time, damaging the surrounding materials. Earthquake damage in 1997 to the Basilica of San Francesco in Assisi, Italy, was partly due to interventions in prior decades. “Behind this kind of intervention there is fear, ignorance, in some cases greed,” says Huerta. “An expensive intervention is much better business than a moderate [one], or even no intervention.”

Engineers today have plenty of high-tech tools to assess older buildings; they scan surfaces with lasers, study cracks with thermal imaging, and analyze the microscopic structure of materials. Most engineers also use modeling techniques adapted from modern-day buildings, which focus on properties of the materials and stresses present throughout a building. Finite element models, which divide a structure into small parts and calculate the stresses in each one, create beautifully detailed meshes of high-stress areas, and can predict a building’s behavior in response to earthquakes or other perturbations.

Ochsendorf says modern finite models can lead to a misdiagnosis that a masonry building is unsafe. He and likeminded engineers prefer an approach based on plasticity theory called limit analysis, which is closer to traditional ways of thinking about buildings—as a problem of geometry. Ochsendorf and his colleagues treat a building as an assemblage of rigid blocks, and find a way that the configuration of blocks can be held in equilibrium, under only compressive forces. They examine conditions, whether an uneven foundation or an earthquake, that could compromise its stability. Ochsendorf lets the building crack as much as it wants to and asks: Will it still stand?

Unlike many modern engineers, John Ochsendorf fights the impulse to control, fix, and correct. That was obvious when he had the opportunity to help create a new masonry structure that was built this spring.

His colleague J. Meejin Yoon, head of MIT’s architecture department and principal at Höweler + Yoon Architecture, designed a memorial for Sean Collier, the MIT police officer who was killed in the days after the Boston Marathon bombing in 2013. She designed a structure of five walls made of 32 granite blocks that come together to form a shallow vault; curved spaces through the walls form passages and windows under it.

The memorial is both a tribute to ancient construction and a feat of modern technology. Yoon consulted with Ochsendorf’s team, using software they designed and 3-D printed models, to create a vault that looks impossibly flat yet relies on compression to hold the stones in equilibrium.

But some of the project’s structural engineers deemed the original design risky. They insisted on steel dowels to stabilize the stones, which would be fixed with grout. Ochsendorf believed the memorial was stable with just stones. But the engineers went ahead with the steel dowels.

Most stone arches are assembled from the bottom up, with a keystone at the top holding the structure in place. The memorial was assembled from the top down, each stone placed by crane onto a metal scaffold over the course of several weeks. But on a sunny day at the end of March, the scaffolding was to come down, leaving a brief opportunity to let the stones come to rest as a pure compression vault, steel dowels loose in their holes, before the structure was grouted into place.

When I arrived, the construction site was filled with about 25 students, workers, and engineers who had contributed to the project and wanted to see this assemblage of stones off its supports, including Collier’s stepbrother, who had been managing the project for Suffolk Construction. Four workers gathered on the scaffold and lowered posts by turning cranks in unison, in increments of 0.031 inches. After each round, a team of graduate students checked the weight on scales at the bottom of the scaffolding and measured any movement at the joints. If it settled within predicted parameters, Ochsendorf would feel that his original calculations were justified.

When half of the load had been transferred to the stones, the center of the vault had dropped by five millimeters. “It’s pretty much right on prediction,” he said, slapping my shoulder a little too hard. “It doesn’t mean we’re totally out of the woods yet, but it’s a pretty good day so far.”

Jim Durham, a representative of the stone fabricator, Quarra Stone Company, had come from Madison, Wisconsin, to be there. He said that in the future, someone might wonder how the memorial stood up, and be told it had steel dowels inside. “Today we found that it’s not the dowels that hold it up—it’s the compression that holds it up,” he said. “The purists among us today are going to declare victory.”

In the end, with 95 percent of the weight transferred from the scaffold, the center of the vault dropped just six millimeters, which Ochsendorf said is “insanely small.” To the naked eye, nothing had happened. But for him, the experience showed that it’s possible to build high-tech, modern structures using ancient principles and materials. “Under its own weight, it’s held up as a gravity structure, stone balanced against stone,” he said. Just as so many buildings have stood for centuries.

Ochsendorf insists that his goal, like that of every structural engineer, is to ensure that buildings are safe. But sometimes intervening is the easy way out. “Not intervening is a really difficult thing to do,” he says. “You have to have the ability to say, ‘I’ve seen that crack, it doesn’t worry me, I think the building is safe.’ ”

The Pantheon is not currently being eyed for a retrofit, but Ochsendorf wants to help it and similar buildings avoid the fate of Rome’s Trajan’s Market, from a similar era as the Pantheon; a network of ugly steel supports was installed several years ago based on finite element modeling of stresses in its walls.

To do that, he wants to show what real failure looks like. “There have been reams and reams of papers and dozens or hundreds of books on the Pantheon, but no one has ever computed the collapse state before—what would it take to make the Pantheon fall down?” he says.

And now, he’s beginning to do that. After the model was carefully assembled, his students tipped it gradually—a proxy for the horizontal forces of an earthquake. As the ground moved, the blocks began to loosen their hold on one another—leaving gaps akin to cracks that might appear in concrete—but the structure itself held together. Until it didn’t. Eventually, the leading edge pitched forward and blocks collapsed spectacularly into rubble.

The experiment showed when the Pantheon would fail and how: which parts hinge and topple first. Now they’ll combine what they learned from the block experiments with computer models and structural theory. The resulting analysis, Ochsendorf says, “will provide us with ammunition if someone were to question the safety of the monument and propose a heavy-handed intervention.” While it did eventually give way, it proved to be surprisingly resilient. “Fundamentally, the model shows us just how stable the Pantheon really is,” he says.

Courtney Humphries is a writer in Boston who covers science, medicine, architecture, and urban planning.

Lead image courtesy of Gjon Mili/The LIFE Picture Collection/Getty Images.